Investing in a 5000-liter stainless steel water tank can be a significant expenditure, but its long-term benefits often outweigh the initial costs. These tanks are designed to withstand harsh conditions and provide safe, reliable water storage for years. As you consider your options, it's crucial to assess your specific needs, the factors influencing price, and the long-term value offered by various models. Whether it’s for home use, agricultural purposes, or industrial settings, finding the right tank at a fair price will ensure that your water storage solution meets your expectations without breaking the bank.

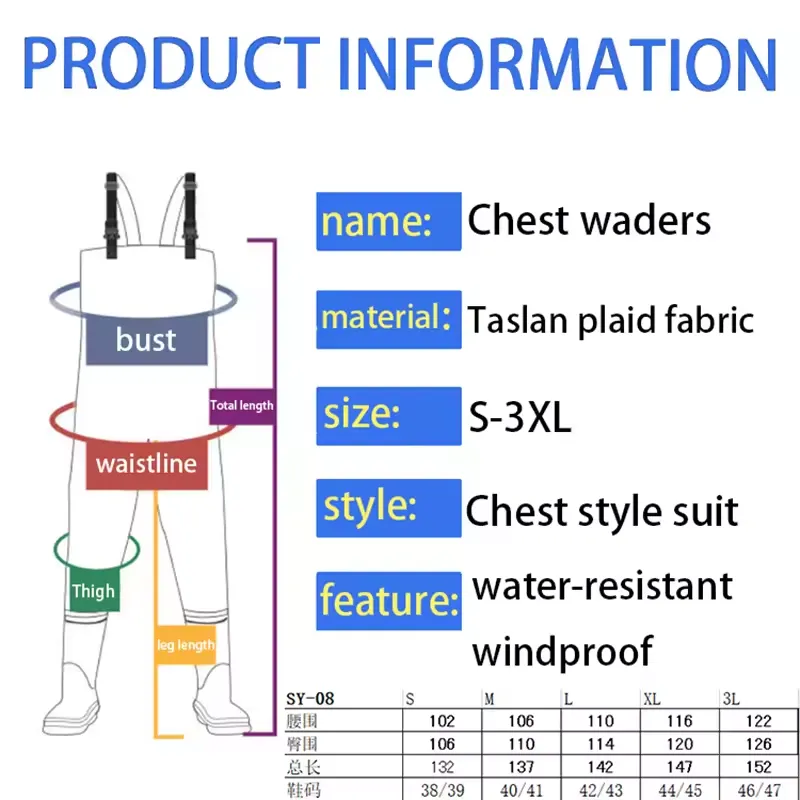

Brands often incorporate additional features like insulation for cold weather, anti-slip soles, or even built-in drainage systems, enhancing their usability Brands often incorporate additional features like insulation for cold weather, anti-slip soles, or even built-in drainage systems, enhancing their usability

Brands often incorporate additional features like insulation for cold weather, anti-slip soles, or even built-in drainage systems, enhancing their usability Brands often incorporate additional features like insulation for cold weather, anti-slip soles, or even built-in drainage systems, enhancing their usability Ensure the waders aren't too long, as this could cause tripping or restrict movement Ensure the waders aren't too long, as this could cause tripping or restrict movement

Ensure the waders aren't too long, as this could cause tripping or restrict movement Ensure the waders aren't too long, as this could cause tripping or restrict movement

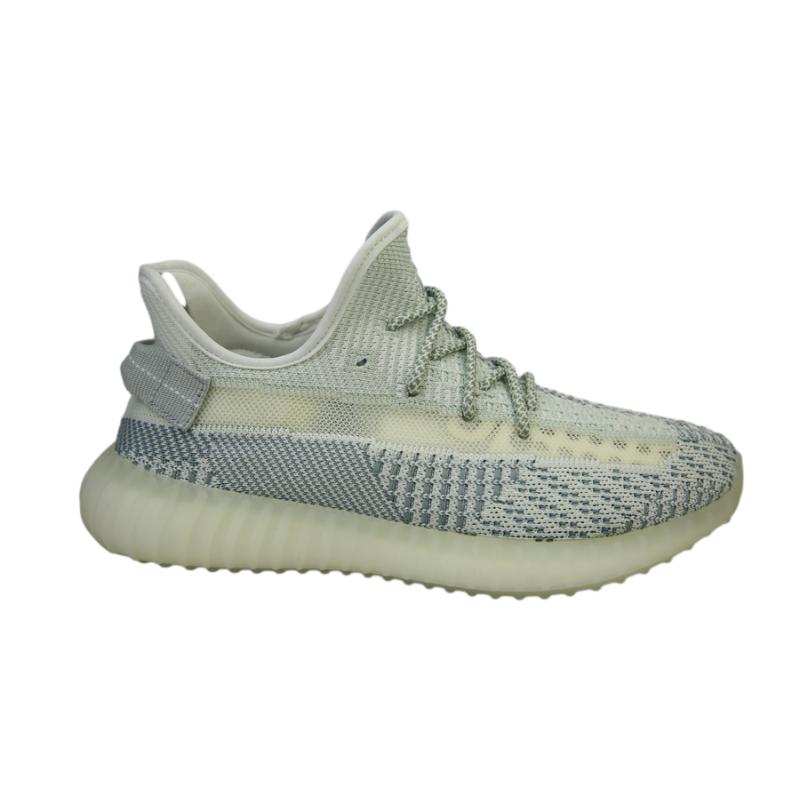

Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb

Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb Moreover, rubber is known for its robustness and grip, which means these boots can handle both urban sidewalks and more rugged terrains with equal aplomb

The head is formed at one end, while the other end is cut and shaped into a sharp point The head is formed at one end, while the other end is cut and shaped into a sharp point

The head is formed at one end, while the other end is cut and shaped into a sharp point The head is formed at one end, while the other end is cut and shaped into a sharp point